San José Dairy, Argentina

Mauricio Álvarez, together with two of his brothers and his father, run a family business with three dairies, all of them on leased land, as well as a cheese factory. The business began in 2004, milking eight cows in a basic abreast direct-to-can parlor. Today, about 500 cows are milked across the whole company.

Home San Jose Dairy Argentina

Mauricio Álvarez, together with two of his brothers and his father, run a family business with three dairies, all of them on leased land, as well as a cheese factory. The business began in 2004, milking eight cows in a basic abreast direct-to-can parlor. Today, about 500 cows are milked across the whole company.

“We used to recognize metabolic disease when the signs were already too obvious and it was very difficult to rehabilitate the cow. Now, with Allflex technology, we spot it 10 days earlier.”

Mauricio Álvarez, Co-Owner

Challenges

Adopt technology to continue increasing scale, keep the system simple, facilitate daily work for staff and reduce cow mortality and culling rates

System

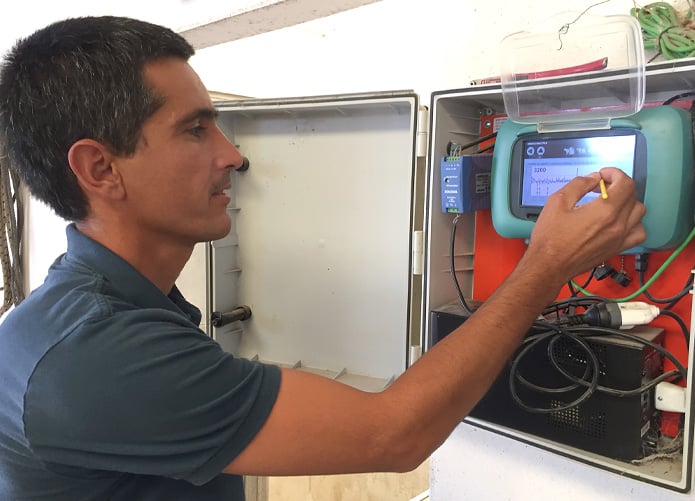

Allflex Heatime® Pro System with HRLDn tags for real-time heat detection and health monitoring.

Benefits

Heat detection increased from 60 to 73%, cow mortality dropped from 15% to 7% and time-consuming visual heat detection role has been eliminated, freeing up labor resources

At a Glance

- Company: San José Dairy

- Location: Diego Gaynor, Buenos Aires Province, Argentina

- Herd Size: 300 cows

Summary

The Allflex solution has improved reproductive, mortality, and culling rates, as well as the quality in everyday work. The latter is particularly true in terms of time-savings in heat detection. “For three years now we haven’t needed to have a dedicated employee deal with heat detection,” says Mauricio.

You may also find these testimonials interesting